What Services we are provide to you

Excavators feature a powerful hydraulic system that moves the boom, arm, and bucket for a wide range of work, including digging, material handling, and demolition. Key work features include a versatile attachment system with various tools like breakers and augers, 360-degree rotation, and an undercarriage that is either tracked or wheeled, providing mobility and stability

Key components and features Hydraulic system: The engine powers the hydraulic system, which uses fluid pressure to precisely control the movement of the boom, arm, and bucket, eliminating the need for brute force. Working group: Boom: The main arm attached to the house. Arm (Dipper/Stick): The section connecting the boom to the bucket. Bucket: The tool at the end of the arm for digging and moving materials. Cylinders: Hydraulic cylinders articulate each part of the working group. Rotation: The cab, known as the "house," can rotate up to 360 degrees, allowing the operator to work in any direction without moving the base. Undercarriage: Crawler tracks: Provide superior stability and off-road capability. Wheels: Offer greater speed and maneuverability for transportation.

Learn More

Pile Driving Part I: Introduction to Hammers and Techniques ...Pile driving is a construction method used to embed long, slender columns called piles into the ground to create a stable foundation for structures like buildings, bridges, and offshore platforms.

How it works A pile driver, a large machine, uses a heavy weight or other forceful mechanism to repeatedly strike the top of a pile. The impact drives the pile deeper into the soil, displacing the earth around it until it is fully embedded. The process continues until the pile reaches its target depth or a specified resistance is achieved, providing a solid and stable foundation. Types of pile drivers Impact hammers: These can be diesel, air, or steam-powered. They use a ram that strikes the pile with high impact force. Hydraulic hammers: Use hydraulic power to lift a piston or ram, which then strikes the pile, often providing more control and a higher blow rate. Vibratory drivers: Use high-frequency vibrations to help the pile penetrate the soil. This method can be less noisy and is useful in certain soil conditions, but the vibration needs to be monitored to avoid impacting nearby structures.

Learn More

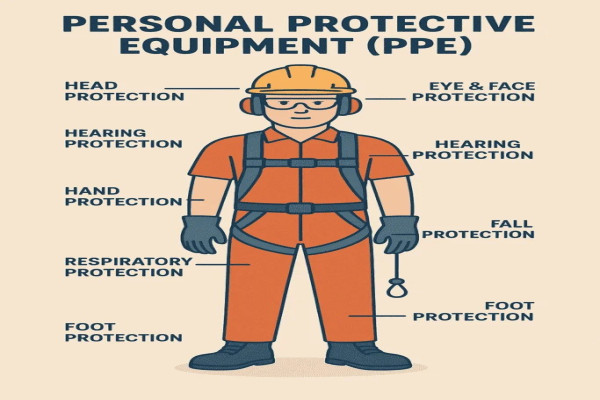

Safety is our priority," "Be aware, take care," and "If you think safety is expensive, try an accident"

Construction safety involves measures to prevent accidents and injuries on a job site by using proper Personal Protective Equipment (PPE), following safety regulations, conducting regular equipment inspections, keeping the site clean and organized, and providing comprehensive safety training.

Learn More